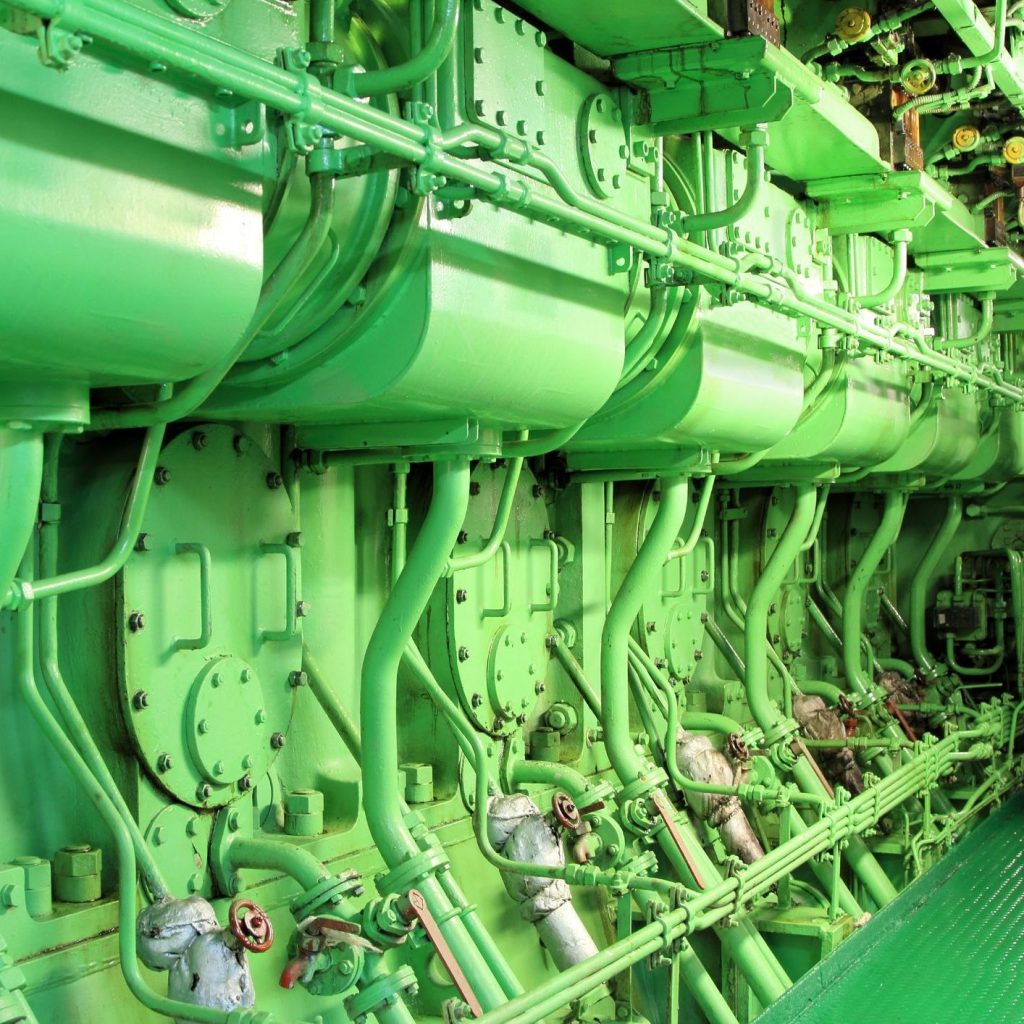

Engine Spare Parts – Engine spare parts are critical to the reliable operation and maintenance of ships, as they directly impact the performance and longevity of the vessel’s propulsion and auxiliary systems. Given the demanding conditions at sea, engines experience significant wear and tear, necessitating the availability of spare parts to ensure smooth operations. These components include items such as pistons, crankshafts, bearings, gaskets, filters, and fuel injectors, which are essential for maintaining engine efficiency, reliability, and safety. Regular maintenance and timely replacement of worn-out parts help prevent breakdowns, reduce the risk of engine failure, and avoid costly repairs during voyages. Moreover, having a well-stocked inventory of engine spare parts is crucial for minimizing downtime during routine maintenance and emergency repairs. The ability to quickly replace faulty components ensures that ships can remain operational and adhere to strict schedules. In addition to propulsion systems, spare parts are also necessary for auxiliary machinery, including generators, pumps, and compressors, which support various onboard functions like power generation and water management. By ensuring the availability of quality engine spare parts, ship operators can enhance the overall efficiency, safety, and performance of their vessels, ultimately contributing to successful maritime operations and reducing the risk of accidents at sea.

Filters – Filters are crucial components in ships, serving to protect various systems and enhance the efficiency and longevity of onboard machinery. They are employed in several applications, including fuel, oil, air, and water filtration, ensuring that contaminants do not compromise the performance of critical systems. For example, fuel filters remove impurities and particles from fuel before it enters the engine, preventing clogging and ensuring smooth operation. This is essential for maintaining engine performance and reliability, particularly in harsh maritime environments where fuel quality may be compromised. In hydraulic systems, filters help maintain clean hydraulic fluid, preventing damage to pumps and actuators caused by dirt and debris. Air filters are vital for the ship’s ventilation and engine intake systems, ensuring that only clean air enters engines and living quarters, thereby maintaining air quality and reducing wear on machinery. Additionally, water filters are used in freshwater systems and ballast water management, protecting pumps and ensuring compliance with environmental regulations. By effectively removing contaminants, filters contribute to the overall safety and efficiency of ship operations, reducing maintenance costs and downtime. Regular inspection and replacement of filters are essential practices that support the reliable operation of a vessel and enhance its operational lifespan.

Petroleum Products – Petroleum products are vital for the operation and maintenance of ships, serving multiple functions critical to maritime activities. The primary use of petroleum products is as fuel; marine vessels typically rely on marine diesel oil (MDO) or heavy fuel oil (HFO) to power their engines. These fuels provide the necessary energy for propulsion, enabling ships to navigate across vast oceans and transport cargo efficiently. Additionally, lubricants derived from petroleum are essential for reducing friction in engine components and ensuring smooth operation, thereby prolonging the life of the machinery and enhancing overall performance. Beyond fueling and lubrication, petroleum products also play a role in various onboard systems, including heating, cooling, and electricity generation. Ships use heating oil for maintaining comfortable temperatures in living quarters and ensuring that machinery operates effectively in colder environments. Furthermore, petroleum-derived products are used in hydraulic systems to facilitate the operation of deck machinery, steering gears, and cargo handling equipment. In terms of safety and environmental considerations, ships must adhere to strict regulations regarding the storage, handling, and disposal of petroleum products to minimize pollution and ensure compliance with international maritime standards. Overall, petroleum products are indispensable for the efficient and safe operation of maritime vessels.

Joints & Bearing – Joints and bearings are critical components in ships, playing essential roles in ensuring smooth operation, structural integrity, and longevity of marine equipment. Joints serve as connection points between various parts of the ship, allowing for flexibility and movement where necessary. They are commonly used in the assembly of structures, machinery, and piping systems, ensuring that different components can function together seamlessly. For example, in the propulsion system, joints connect shafts and other mechanical parts, allowing for efficient power transfer while accommodating the ship’s movement and vibration. Bearings, on the other hand, support rotating or moving components, reducing friction and wear between surfaces. They are essential in various applications, including propeller shafts, rudders, and winches, where they facilitate smooth rotation and motion. High-quality bearings ensure that these systems operate efficiently, minimizing energy loss and mechanical wear, which is particularly important in the harsh marine environment where saltwater and heavy loads can accelerate deterioration. By providing stability and support, joints and bearings contribute significantly to the safety and reliability of a ship’s operations. Proper maintenance and timely replacement of these components are crucial to prevent mechanical failures, ensuring that the vessel remains seaworthy and capable of withstanding the rigors of maritime activities.

Pneumatic & Electrical Tools – Pneumatic and electrical tools are indispensable for the efficient operation, maintenance, and repair of ships, significantly enhancing productivity and safety onboard. Pneumatic tools, powered by compressed air, are commonly used for tasks requiring high torque and speed, such as drilling, grinding, sanding, and cutting. Tools like air impact wrenches, pneumatic drills, and sanders facilitate the rapid completion of maintenance tasks while reducing physical strain on the crew. The portability and power of pneumatic tools make them particularly effective in the confined spaces and challenging environments often found on ships. Electrical tools, on the other hand, offer versatility and precision in various applications. Electric drills, saws, and grinders are widely used for fabrication and assembly work, enabling crew members to perform tasks with improved accuracy and efficiency. These tools are essential for tasks such as installing equipment, repairing structures, and conducting routine maintenance. Additionally, both pneumatic and electrical tools contribute to improved safety by reducing the risk of accidents associated with manual labor. The integration of these tools into ship operations not only accelerates workflow but also enhances the overall reliability and performance of the vessel, ensuring that it remains seaworthy and operational in diverse marine conditions.